Our Products

- Rolling Mill Stand

- Housingless Mill Stand

- Helical Gears

- Reduction Gearboxes

- Pinion Gearboxes

- Reduction Cum Pinion Gearbox

- Speed Increaser

- Flywheel

- V-Belt Pulley

- Gear Coupling

- Spindles

- Rollar Guide Box

- Bearing Chokes

- Flying Shear

- Continuous Rotating Shear

- Crop & Cobble Shear

- Cold Shear

- Billet Shear

- Rotary Shear

- Hot Saw

- Roller Conveyor

- Quenching Boxes

- Twin Channel

- Cooling Bed

- Furnace Pusher / Ejector

- Pinch Roll & Tail Breaker

- Vertical Edger

- Straightening Machine

- Bar Bending Machine

- Tying Machine

- Cardan Shaft

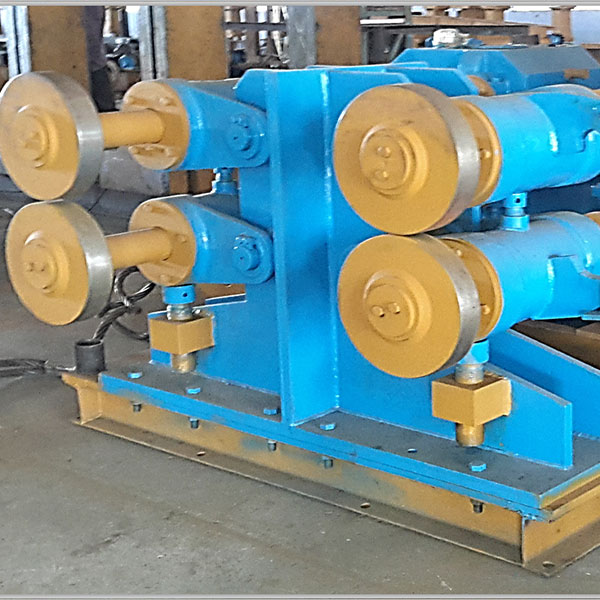

Pinch Roll and Tail Breaker

Manufacturing & Exporting the best quality of Pinch Roll and Tail Breaker

MKES is manufacturing High speed Pinch used at different location in rolling mill along with before TMT quenching box and after TMT quenching box to provide consistent Tension of the Bar. The use of 2 Hi Gear Box, Solid Rolls with Cardon Shaft provided in these DC Pinch Rolls helps in achieving uniformity in operations.

Specification :

| Material | M.S. Prime Plate, Graded Cast Iron |

|---|---|

| Base | Mild Steel Prime Plate Fabricated |

| Size | 205 mm to 360 mm (as per requirement of mill) |

| Barrel Length | As Suitable to the Pinch Roll. |

| Chocks | Steel Chocks fitted in Pinch Roll for Spherical Roller Bearing |

| Bearing | Imported Spherical Roller Bearing |

| Shaft | Jointing with Cardon Shaft |

| Gear Box | Includes Forged Steel Single Helical Gears with all accessories |

Feayures :

- Cantilever and pneumatic type Pinch Roll & Tail Breaker up to 360 MM CRS.

- Top roll raised pneumatically or lowered with bottom roll in adjustable finish.

- Pinch roll housing comprising sturdy welded construction.

- Pinch rolls feature wear resistant surface with anti friction bearing mounting support.

- Spindle provided for meeting the needs of adjustment of bottom pinch rolls

- Pinch rolls featuring use of sensors that allows precision breaking up to speed of hot flowing material.