Our Products

- Rolling Mill Stand

- Housingless Mill Stand

- Helical Gears

- Reduction Gearboxes

- Pinion Gearboxes

- Reduction Cum Pinion Gearbox

- Speed Increaser

- Flywheel

- V-Belt Pulley

- Gear Coupling

- Spindles

- Rollar Guide Box

- Bearing Chokes

- Flying Shear

- Continuous Rotating Shear

- Crop & Cobble Shear

- Cold Shear

- Billet Shear

- Rotary Shear

- Hot Saw

- Roller Conveyor

- Quenching Boxes

- Twin Channel

- Cooling Bed

- Furnace Pusher / Ejector

- Pinch Roll & Tail Breaker

- Vertical Edger

- Straightening Machine

- Bar Bending Machine

- Tying Machine

- Cardan Shaft

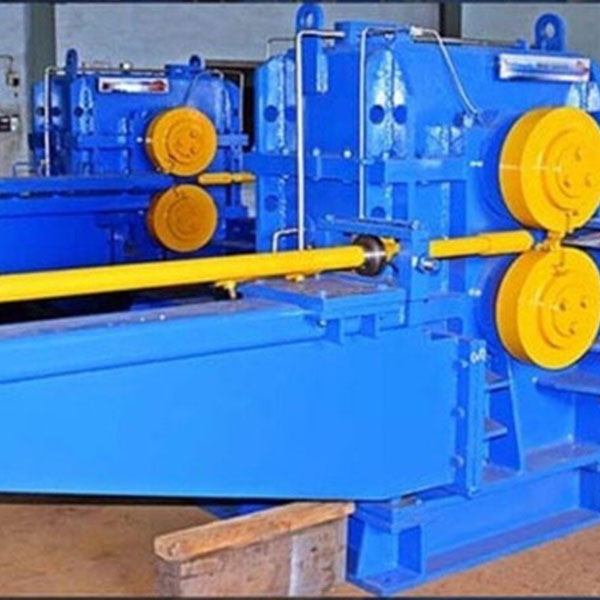

Continuous Rotating Shear

It is designed to provide consistent cutting support for bars at desired lengths

The Start Stop Flying Shear can cut upto 18m/s with the standard DC motors. The Solutions lies in installing High Speed Continuous Rotating Shear with regenerative Tail Breaking Pinch rolls.

Continuous Shear offered comprises shears up to 500crs. The offered latest technology based machine can offer precise cutting of bars from 12mtr/sec up to 32mtr/sec. Further, with all internal support systems/parts of machine being hardened & grinded as well as durable fabricated outer body finish also makes the machine deliver optimum performance support in given end applications.

Technical and Design specification of the Continuous Rotating Shear:

- 8mm to 16mm TMT bar. Single Shear is sufficient for ingot rolling mills.

- The first cut of this shear is not accurate, but the subsequent cuts are very accurate. The material loss of first cut is compensated by the subsequent cuts.

- The motor power is only 50 KW, compared to 90, 130, 175 KW of Start Stop Flying Shear.

- The casing is vertically split to take the separating force during the the milli seconds when the cut is executed on the casing profiles instead of parting bolts.

- The blade holder is fitted with double cone torque couplings as a safeguard against the accidental overload.

- The Flywheels are provided to reduce the motor power. The flywheel intertia augments the cyclic cutting load.

- The gears are case carburised hardened & ground designed for minimum back lash.

- Shifter present for moving bars in path of blade

- Presence of servo motor for shifting line of rolling

- Shifter mechanism at shear exit where shifting is performed through pneumatic mechanism

- Main shear body with cover provided for safety of men & machinery